FIVE KEY ASPECTS OF ENGINEERING DESIGN AND MANUFACTURING

What a difference a year makes. The pandemic has changed the way we all live, work and play, and it’s never been more important for businesses to get their tech in check. All this change means that it’s been an incredible year in the world of engineering design and manufacturing. It’s certainly been a kick towards understanding the need to get our analogue processes talking digital.

Don’t have time to read the blog now? Click the button to download and read at your leisure…

The Rise of Innovations in Engineering Design and Manufacturing

It’s been just over a year since we were thrust into remote working life. I don’t think any of us could have predicted that the world of work and communication would change so drastically in such a short space of time. Virtual working had been increasing before the pandemic, but that sudden influx of people needing more online systems further drove the need for remote monitoring and deployed electronic products. To achieve their goals and stay ahead of the competition, many businesses have found a need to rapidly develop their products and ideas. And to successfully deliver, innovation in engineering and technology design is a must have.

The desire for rapid development, coupled with large scale component shortages, means that careful management of the development process has never been so imperative. Project management, technology strategy and agile development are more important than ever before.

Have you been struggling to get your product to market?

Well-defined, agile engineering design and manufacturing processes allow for streamlined development. As a result, improved hardware, firmware and software design processes can be seen in system development across all design genres. The right productivity tools allow for greater customer transparency, and monitoring for performance metrics enables effective project management from start to finish. And your project management does need to be faultless, because managing risk is an important factor in avoiding costly and time-consuming errors.

The Five Fundamental Factors of Engineering Design and Manufacturing

DESIGN

Whether your project is a simple sensor amplifier, or a complex data logging system, there are certain risks you must consider when undertaking a new design. Your project structure and size need be taken into account. You need to identify what your requirements are and create well-defined specifications. And all aspects of your project need consideration from system to low-level functions. Another side-effect of the pandemic has meant that, more recently, component availability has become a high priority design consideration. On top of this, you have to understand the technical capabilities of your staff and internal resourcing. All of which can affect the delivery of your product.

SIMULATION

Do you know your Analogue signals? How is your power supply going to respond to transients? It’s important to understand signals from the real world in order for you to get the most accurate measurements out of your sensors, especially if your product is wireless. Simulation is a key tool in an engineer’s arsenal and a design-heavy approach can be paramount to successful delivery.

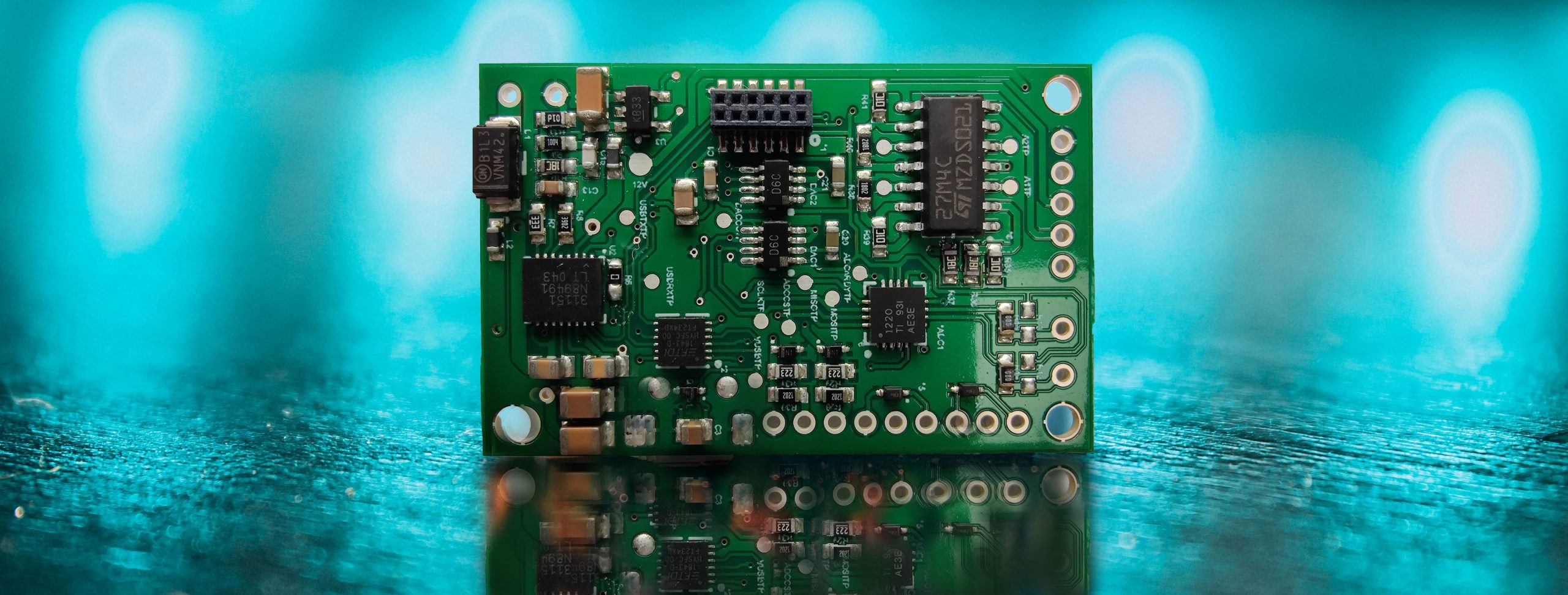

HARDWARE DESIGN

Are you up to date with the latest component data? Do you have access to the right CAD tools? Hardware engineering design requires a clear understanding of circuit simulation, schematic design and capture, and PCB layouts. Getting the hardware right is the first step towards successful development.

FIRMWARE DESIGN

Embedded processors often form the core of embedded systems. Their programming ultimately defines your product’s behaviour and performance. Design options surrounding the choice of device and its defined behaviour can have far reaching effects on your product, but also on the systems it interacts with. Clear, concise documentation and robust design are crucial to delivering a working product to your required specifications.

SOFTWARE DESIGN

Do you have knowledge of how to tailor your software to suit your needs? Will you be able to accurately display and analyse your data? If not managed properly, your hardware and software design can become like a chicken and egg situation. You need to understand your hardware and firmware to understand your software… to understand your hardware to understand your software. Sound design specifications and communication protocol definitions remove any disconnect between software and hardware.

Ultimately: Is Your Technology Strategy Watertight?

So you have a product or project in mind, but what’s your action plan? It’s important to consider anything that may impact the design and lifecycle of your product and that can be a lot. In fact, life cycle, component selection and manufacturing processes all need to be mapped out before you even take your first step. All of this is why an agile development process, with strong project management, is important when you undertake engineering design projects.

There’s a lot to consider when you take on an engineering design project. When we start managing a project, we cover all bases to ensure the ongoing success of the product.

– Dr Neil Curry

Taking Your Product from Idea to Reality

We’ve created a pdf download detailing just a handful of our services, covering all elements of engineering, design and manufacturing that will give you some ideas on how your product can become a reality… and how you tie that reality into the cloud. Whatever your awesome product is, we have you covered. We are adept at analogue and digital hardware, embedded processes, data collection and connection to “The Cloud”, and will project manage the delivery of your product, so you have all the support you need, every step of the way.

Download your free booklet to learn more

Sign up to our Newsletter for engineering design and manufacturing insights…

STILL HAVE QUESTIONS OR WANT TO GET IN TOUCH?

Our office hours are 9am until 5pm, but feel free to contact the team and we’ll get back to you as soon as possible.