PROGRAMMABLE AMPLIFIERS

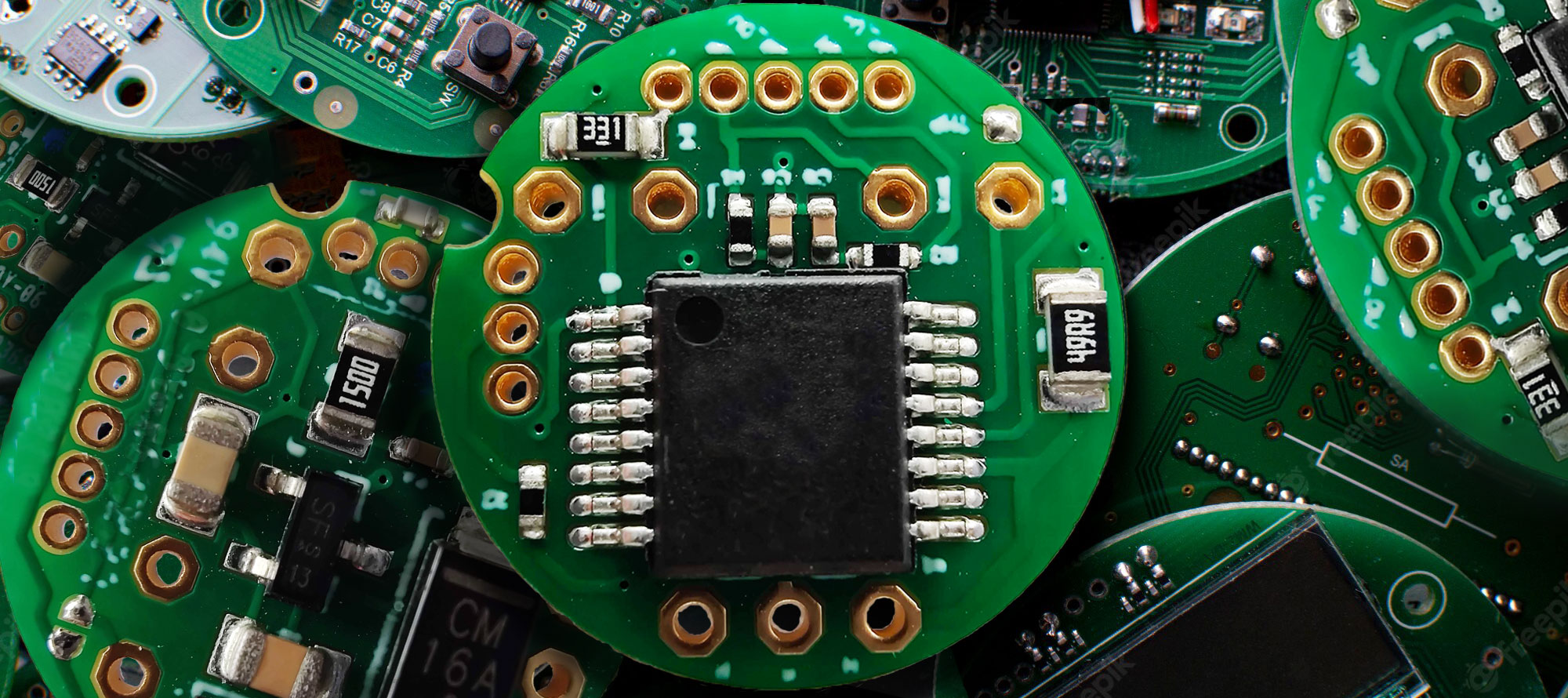

Capable of operating at high temperatures. Providing real-time sensor element compensation. Enabling automated calibration during production. These programmable amplifiers take the real world and turn it into a useful signal.

Don’t have time to read the blog now? Click the button to download and read at your leisure…

Sensor Electronics

Sensors are all over the place. Monitoring environments, reporting back their findings for analysis and facilitating improvement. They are ubiquitous in everyday life, used by virtually every industry in the modern world.

Sensor electronics are now fundamental to the way we live. They create safer environments without us even realising that they’re there. Giving us the insights we need to further understand the condition of our equipment.

Generally, changes in the real world induce very small changes in the electrical one. There’s a limit to what sensor products can pick up on without amplification, and small changes like this are tricky. These tiny signals can skew measurements. However, without accurate data readings, it’s impossible for sensors to produce useful outputs. Amplifiers need to be calibrated with the sensor in order to report accurate data, in many cases. That’s the beauty of choosing programmable amplifiers over manual calibration. Programmable amplifiers provide variable amplification of minute signals. They also compensate for other unwanted changes that may compromise your measurements. For example, when it comes to temperature dependence.

It’s all about automation in the future of programmable amplifiers.

The Trouble with Sensors

EVER DECREASING SIZES

Programmable amplifiers should be at the core of most sensors. Therefore, they need to keep up with the demands of increasingly compact sensor elements and tighter specifications. Shrinking physical dimensions and increased processing capabilities mean that more can be achieved in the same package when it comes to resolution, accuracy and bandwidth. Experience of adapting to an ever changing environment is essential. As well as keeping up with demand for continual improvement. For this reason, it’s vital to keep your tech up to date.

We all know that modern life is fast paced. Everyone is looking for the next big thing that will enable effective data analysis. Whether through conventional methods, machine learning or AI. The thing that enables that level of analysis is usually data found in the real world. And that calls for products that are smarter and more effective through smaller and smaller electronics. So it’s important to have in-depth knowledge of what is technologically possible. And how to deploy miniaturised electronics into tough environments.

SENSOR ACCURACY

Ultimately, the data you get from your sensors needs to be accurate. On the whole, that means constant compensation for external factors, which has to be done electronically. As we’ve pointed out, changes in the real world often bring about minute physical changes. These changes induce tiny electrical changes in the materials that are the basis of most sensors. Other external Influences can also bring about similar changes. Without proper compensation you could see errors that skew your data readings. So it’s incredibly important to understand how to effectively compensate for the small factors. And considering the ways that programmable amplifiers can enhance your data readings is a key step to reliable data.

SENSOR COMPENSATION AND CALIBRATION

Sensor manufacturers often use time-consuming, manual processes for calibration. Manual methods are complicated, drawn out and costly. But calibration is essential if you want to ensure the accuracy of your readings. Automated calibration and the onset of Industry 4.0 provide new and innovative ways to perform calibration smartly.

Programmable Amplifier Automation

There are exciting innovations in the long-term vision of sensor electronics. Programmable amplifiers enable factory automation on a large scale. When it comes to fully-automated calibration rigs consisting of pressure, force and temperature controllers, for example.

An extremely high-precision sensor can be created and calibrated repeatedly, without the need for human interaction. This saves both time and resources while providing full traceability and reliability. No longer will human error endanger the quality of the finished sensor assembly. Data gathered can be used for statistical analysis to further improve manufacturing processes and the products themselves.

I.C.E. ELECTRONICS SOLUTIONS FOR PROGRAMMABLE AMPLIFIERS

I.C.E. Electronics has developed a solution to replace manual calibration with our advanced processing and automation for programmable amplifiers. We offer a range of programmable amplifiers from simple to complex, and can tailor our standard designs to fit your requirements. Alternatively, we can create fully customised solutions to suit your needs.

At the simplest level, we design amplifiers which are just that – static signal amplifiers. At the more complex level, we offer amplifiers with the capability to do real-time digital signal processing, such as polynomial correction over multiple parameters. This enables devices to compensate for both process and thermal errors. We can even go one step further and create custom calibration routines. These can be used to correct very non-linear sensors, or those that have unconventional temperature dependences. Alternatively, they can be used as a base calibration for a product range, saving time in production.

The versatility of our programmable amplifiers means that they can be used to create generic “cores,” which can be reprogrammed to suit application range and accuracy requirements. Thus further reducing manufacturing and calibration times.

We also provide unique, bespoke integration support for production.

PROGRAMMABLE AMPLIFIERS ARE AT THE HEART OF WHAT WE DO

I.C.E. Electronics can help you with any size of project, from small batches right up to large volume production. We help to automate production and calibration through the use of our programmable amplifiers, mass calibration programmers and in-house software resources that talk to your equipment.

We have a wealth of experience in engineering design, test and product development, and market deployment. To complement this, we have specialist knowledge of sensor electronics. This includes interfacing, process correction, signal processing, data acquisition and embedded processing. Our capabilities include hardware design, embedded firmware design (Miro-controller and FPGA), digital signal processing, wireless communications and analogue circuit design.

Market leading technology allows us to work in tight spaces and over extended temperatures (high and low). Our experienced engineers are able to offer a range of solutions to meet customer requirements. We have the ability to deploy electronics into demanding applications in terms of both space and environmental parameters. Including the capability to design electronics that can theoretically operate up-to 225°C at derated performance.

Industry-leading design software and specialist test equipment enables us to complete your design to a high standard. In addition, our portfolio of professional Contract Engineering Manufacturers (CEMs) means that we are able to meet all the requirements of your project or product. We also support it throughout the product life cycle.

Our aim is to help you get the most out of your sensors.

I.C.E. designs and manufactures thousands of programmable amplifiers that find their way into a wide range of sensors.

– Neil Curry

Programmable Amplifiers

From off-the-shelf solutions, to fully bespoke products, we will work with you to develop programmable amplifiers to suit your requirements. You can find out more about I.C.E. Electronics’ Programmable Amplifiers by downloading our free Programmable Amplifiers Flyer.

Sign up to our Newsletter for engineering design and manufacturing insights…

STILL HAVE QUESTIONS OR WANT TO GET IN TOUCH?

Our office hours are 9am until 5pm, but feel free to contact the team and we’ll get back to you as soon as possible.